The Wheel

With the wood and plastic toys now behind him, Godtfred was free to focus all of the companys’ resources and energy on his real interest: the Lego System. The result, not surprisingly, was a dramatic expansion of the System over the next several years.

In 1961 the Futura group began to develop a wheel scaled to the Lego system. It was perhaps Futura’s first important contribution to the Lego System. The wheels were simply round 2 × 2 or 4 × 4 bricks with a groove to accept a rubber tire. The wheel bearing, however, was important enough to justify a patent application. The wheel brick was a 2 × 4 brick with three hollow nylon sleeves that acted as bearings held loosly in place by a plate attached to the bottom. An axle could fit into the sleeve and stay connected by friction and the axle/sleeve assembly was then free to rotate.

The new wheels allowed children to build moving constructions, such as cars, trucks and locomotives. The wheels also signified a new, larger model scale and a shift away from the HO scale town plan.

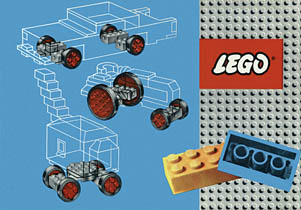

Wheel instructions/ideas, from set 400, 1962–1963

Lego introduced the wheels in the 400 and 401 supplementary sets in 1962. These were followed the next year by several larger sets, such as the European 314 set and the Samsonite 602 Wheel toy. These were followed by the model sets and eventually the wheels, in many diffrerent forms, were offered in nearly all Lego sets. They have become one of the most ubiquitous Lego elements. By the late 1990’s Lego was producing more than 300 million tires a year, making them the largest tire manufacturer in the world.1 1. In terms of absolute numbers, of course.

ABS

Hans Schiess and a visitor in the Process Development Lab, 1964

In 1962 Lego created a process development lab in Billund under the guidance of the Swiss engineer Hans Schiess. One of the first results, based on numerous experiments, was a switch to a new plastic for the bricks: acrylonitrile butadiene styrene (ABS).2 2. Bayer AG (who spun off most of their plastics business as Lanxess in 2004) has long been Legos’ exclusive plastic supplier. They supplied cellulose acetate in the form of Cellidor and, later, ABS in the form of Novodur. Today Lego elements are made of proprietary versions of Novodur ABS and Makrolon polycarbonate which are colored with Macrolex dyes.

Polystyrene, a thermoplastic, was available in commercial quantities since the early 1930’s. It was cheap and easy to mold, but was brittle. To overcome this styrene acrylonitrile copolymers began to be available in the 1940’s. Although stronger than styrene, there were still significant limitations which led, after the war, to the introduction of a rubber (1,3-butadiene) as a third monomer and the development of acrylonitrile butadiene styrene (ABS).

ABS was relatively inexpensive, easy to mold to very tight tolerances, and perhaps most importantly, was much more colorfast, stable and impact resistant than cellulose acetate. Lego began switching over production in 1963 and completely phased out cellulose acetate over the next several years. In North America, however, Samsonite continued to market cellulose acetate elements in certain colors (yellow, e.g.) until 1970.