Godtfred Kirk Christiansen

By the late 1940’s all of the Kirk Christiansen brothers were working in the factory. Karl Georg was in charge of plastics production, Gerhardt was in charge of wood products manufacturing and Johannes was responsible for truck deliveries. Even Ole’s brother, Jens Kristiansen, worked for the company. But it was Godtfred who would take over the leadership of the company.

Godtfred on his 30th birthday, 8 Jul 1950

Godtfred, who by this time was the Operations Director, had spent 10 years with his father learning to manage the business and in 1950, on his 30th birthday, was named Junior Managing Director. From the hand-written letter signed by the entire family:

1. Hansen, Willy Horn. 50 Years of Play. Trans. Charles Napier. Billund: Lego System A/S, 1982. “Sincere best wishes on the Big Day. We want you to know we appreciate and are grateful for what you have done for the company so far. Confident that you will continue to do your best in the interest of the LEGO name, we hereby appoint you today, Saturday, July 8, 1950, junior managing director of A/S LEGO and A/S Kirk Christiansen.” 1

In 1951 Ole suffered his first stroke, beginning a steady decline in his health, and Godtfred had to progressively assume more of the management responsibilities as time passed. In many ways Godtfred seemed an unlikely candidate to run the company. He had barely a high school education and read so haltingly that he would insist his sales managers give him oral reports. He spoke only Danish, but would eventually oversee sales throughout Europe, North America and Asia. What he lacked in formal education, however, he made up with an innate, and sharp, business mind, and perhaps some of his father’s determination and stubborness.

The Part of the Story where Ole Drives Godtfred Insane

And despite his stroke, Ole was still as stubborn as ever and his business relationship with Godtfred was often, at the very least, contentious. In the spring of 1951 Ole decided to shut down operations for the summer, since there wouldn’t be any new orders until the wholesalers and retailers placed their Christmas orders after the summer holidays. Godtfred disagreed and, along with his wife Edith, drove to every customer in southern Jutland and obtained enough orders to keep the factory running through the summer. By the end of the year Godtfred had personally visited nearly every retail customer in Denmark.

The factory and plastic toy production, ca.1953

Sales of both the wooden and plastic toys continued to go well and in 1952 Ole decided to expand the factory, an expansion much larger than what was needed. Godtfred protested the new expansion. After all, they had just paid off the 1942 factory and didn’t need to go right back into debt, but Ole simply said “I’ll decide what's to be built - your job is to raise the money!” The final cost of the expansion was 350,000 DKK. Godtfred was so upset with his father’s plan that he handed in his resignation. This was apparently short-lived and within months Godtfred was showing samples of the bricks to possible export partners in Norway and Sweden. Trips abroad that would pay off a few years later.

The Plastic Toys

The first plastic designs, introduced in 1949, were manufactured using simple one or two-piece molds manufactured by a Copenhagen-based tooling works. Although reasonably well-made, they were certainly no match for the quality of Lego’s wooden toys; but they were also smaller, much less expensive, and most importantly. lent themselves well to mass production.

Over time the molds became better and the toys became more complex and realistic, such as the Halvautomatisk Legetöjspistol or the Ferguson Tracktor model.

There were many different plastic designs. Examples of blocks, such as the Lego Plastic Kubbus or the Lego Plastic Byggeklodser, dolls, spinning tops and even religious crosses were marketed; but most of the plastic toys were based around the same themes as the wooden toys, notably animals, such as the Lego Jersey or the Lego Husdyr, farm equiptment, or vehicles, such as the Chevrolet Modelbiler or the Kabelstyrede Modelbiler.

Plastic toy examples from the 1950’s retailer catalog

The plastic toy design and development occurred in the first half of the 1950’s. After 1955 it appears that most of the company’s resources were used for the new System i Leg and the toy designs were mostly related to the HO scale vehicles and accessories. By 1958 virtually all development was for the new Lego System.

The few wood and plastic toys that remained were marketed under the name Bilofix in 1959 and all non-system toys were finally discontinued in 1960, when the Lego brick became the company’s sole product.

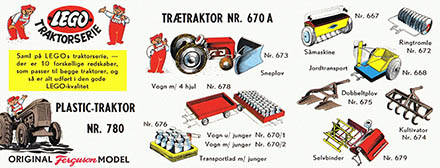

Ferguson Traktor

The 781 Ferguson Traktor, released in 1951, was the most complicated of the early plastic toys and also an early best-seller. The tractor consisted of 15 separate parts that could be assembled into the final model. The tooling and molds cost 30,000 DKK, more than the cost of the real thing - the Ferguson TE 20.

The Tractor was available as a set, the Samlesæt Til Model Traktor, or as individual parts. Lego supplied retailers boxes of parts that could be sold individually; a practice that would continue with the Automatic Binding Bricks and Lego Mursten.

Lego also produced a number of separate farm implements that could be attached to the tractor, such as hoes, cultivators, and even a milk jug sled.

Lego Tracktorserie catalog, 1955

Indre Mission Cross

Although a cross seems an unlikely design, Ole and his family, as well as a significant portion of the Billund workforce, were devout followers of Indre Mission. The crosses, molded with glow in the dark plastic, were not toys but apparently gifts given out around Christian holidays, such as Christmas and Easter. They were also sold or donated to various Christian churches and organizations for use as a fundraiser.

The crosses exist in many different variations and were often molded to order and packaged specially for a specific organization.